The Future of Precision: 3D Laser Scanning Metrology's Impact on Industry

Harnessing the Future: How 3D Laser Scanning Metrology is transforming Quality Control in Manufacturing and Heavy Engineering

In an ever-evolving technological landscape, industries that stand the test of time are those that embrace innovation. One such innovation, 3D Laser Scanning Metrology, is redefining the realms of possibility in the manufacturing and heavy engineering sectors.

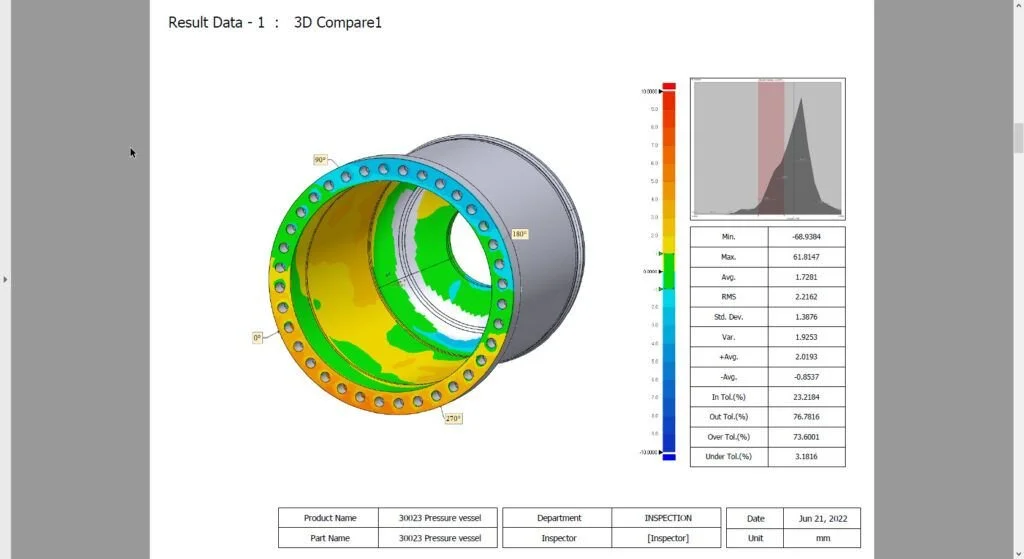

3D Laser Scanning Metrology deploys laser technology to capture the physical measurements of an object digitally, in the form of point clouds. These data points create a high-resolution 3D model of the object, offering a level of precision and efficiency that traditional methods can't match.

How does it work? The scanner projects a laser onto the surface of an object and measures the time taken for the light to reflect back to the sensor. This data enables the calculation of distance with remarkable accuracy, painting a detailed picture of the object's shape and size in three dimensions.

This technology's precision and speed have transformative implications for both manufacturing and heavy engineering. Here are some of the ways it's revolutionizing these industries:

Superior Quality Assurance : 3D laser scanning offers a non-contact method of measuring objects, preventing potential damage to delicate parts. Its high resolution allows for the detection of minute defects that might otherwise go unnoticed. By automating quality control, the technology minimizes human error and expedites the inspection process.

Streamlining Product Development : In an era defined by rapid technological advancements, the speed of product development is crucial. 3D laser scanning facilitates quicker prototyping by enabling engineers to scan, analyze, and tweak designs swiftly. This not only reduces the time-to-market but also fosters innovation by making iterative design more feasible.

Increasing Cost Efficiency : By reducing the time and human resources required for tasks such as quality control and prototyping, 3D laser scanning can significantly lower production costs. Furthermore, its superior precision helps minimize wastage due to errors, making the manufacturing process more cost-effective.

Enhancing Customization and Flexibility : The ability to scan and reproduce components quickly and accurately makes customization easier and more efficient. This is particularly beneficial in sectors like automotive and aerospace, where bespoke parts are often necessary.

In heavy engineering, where the scale of projects often poses significant challenges, 3D Laser Scanning Metrology brings particular transformative benefits:

Large scale engineering projects : In the realm of heavy engineering, where the sheer scale of projects can pose significant challenges, 3D Laser Scanning Metrology offers profound benefits. Traditional measurement methods often struggle with large structures or complex machinery, due to their size and intricacy. However, laser scanning overcomes these hurdles effortlessly, providing detailed, accurate, and swift data capture regardless of the object's scale.

Improved Safety : By providing precise data about structures and sites, 3D laser scanning helps identify potential safety hazards, reducing risks for workers.

Facilitating Retrofitting and Maintenance : The accurate 3D models created by laser scanning facilitate the retrofitting of older structures and the planning of maintenance activities, reducing the potential for costly surprises during the project execution.

The incorporation of 3D Laser Scanning Metrology into the manufacturing and heavy engineering sectors signifies a paradigm shift in how we retrofit, build, and carry out pre-delivery quality controls.