The Shift from Quality Control to Quality Assurance with 3D Scanning

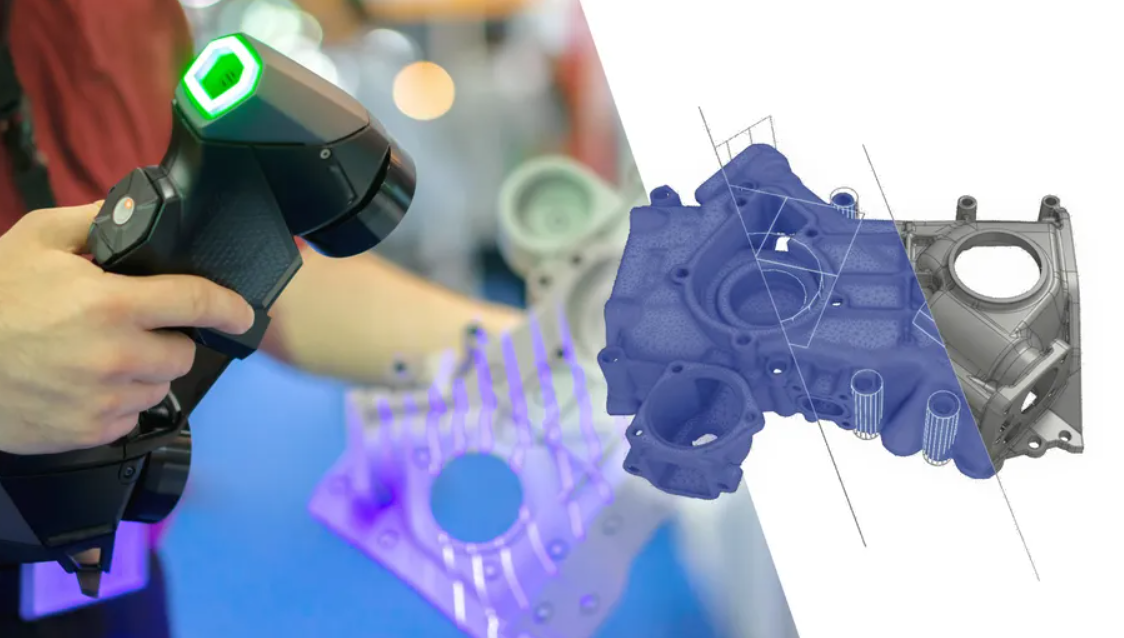

This article integrating advanced 3D laser scanning technology into quality assurance frameworks. By leveraging the unparalleled accuracy and efficiency of 3D laser scanning we suggest a solution that can detect deviations early, mitigate risks, enhance product quality, and streamline production workflows.

The Power of Portable: 5 Ways Handheld Laser Scanning Revolutionizes Manufacturing

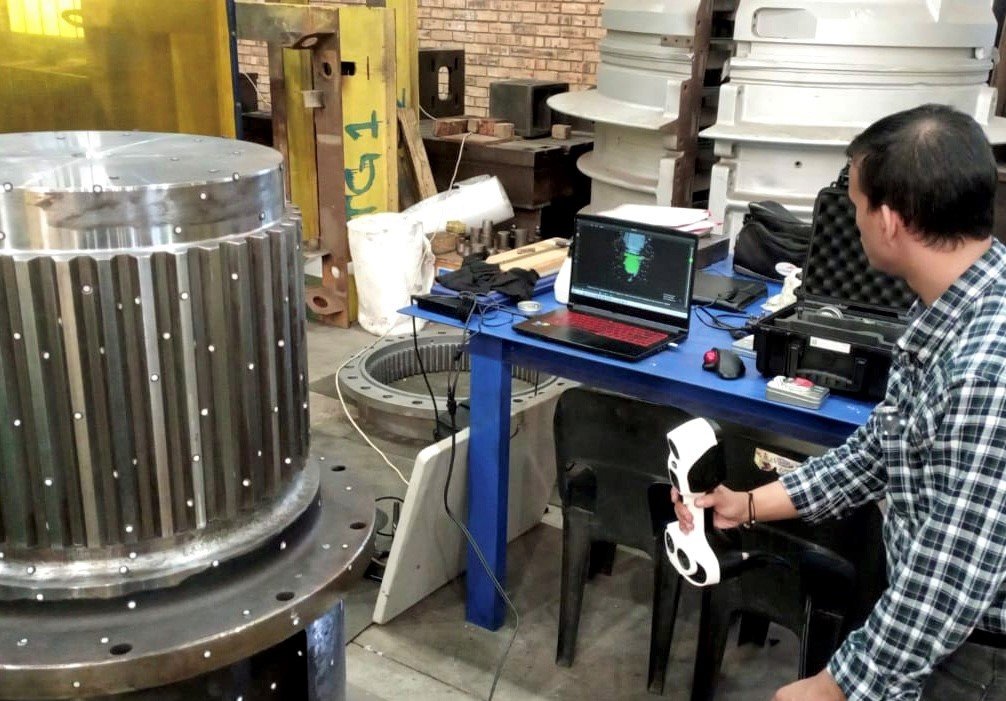

In the world of manufacturing, skilled metrology engineers are turning the tide by harnessing the power of laser scanners right at the production floor. They expertly blend precision measurement and deep understanding of design intent to capture and interpret data beyond standard 'plug and play' procedures. With their ability to pinpoint what to measure, at what tolerances, they directly influence product performance and functionality. As a result, their involvement not only guarantees quality of individual parts but also ensures that the end product delivers optimal performance as intended.

Beyond Verniers and Calipers: Embracing the Age of 3D Laser Scanning

Discover the future of quality control with 3D laser optical metrology. How is this advanced technology, offering non-contact and highly accurate measurements, transforming industries, particularly manufacturing and engineering. Despite initial investment costs, the long-term efficiency, speed, and precision of 3D laser scanning prove to be more cost-effective compared to traditional methods such as verniers, calipers, and gauges. With ongoing technological advancements, expect optical metrology to become an industry standard, yielding significant return on investment.

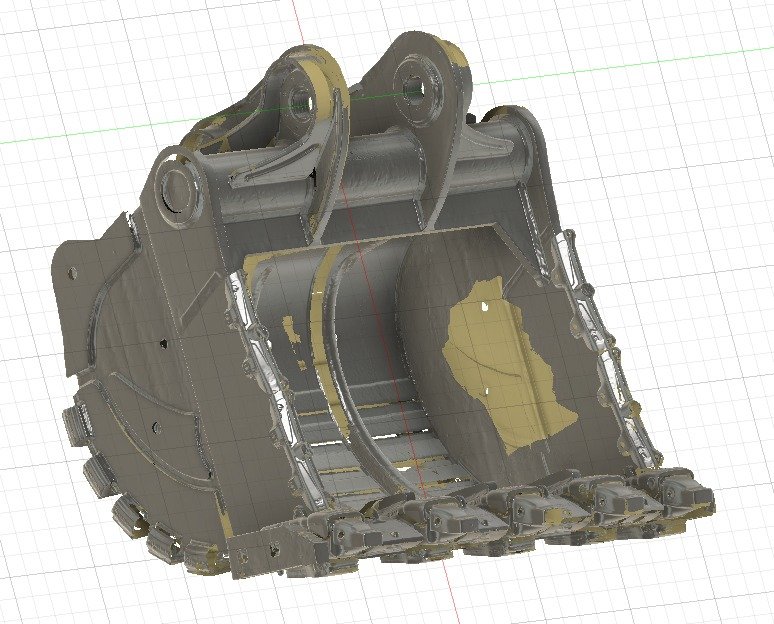

Precision Revolution: Metrology-Grade Scans and Fusion 360 Transforming Reverse Engineering.

Are you ready to unlock the secrets of a product? Metrology-grade scans and CAD models, particularly when combined with the power of Autodesk Fusion 360, are redefining the art of reverse engineering. Dive into a world where high-precision scanning creates a detailed blueprint, enabling engineers to deconstruct, analyze, and understand complex designs, all while improving innovation and product development. Welcome to the future of reverse engineering

The Future of Precision: 3D Laser Scanning Metrology's Impact on Industry

Experience the how quality control abilities in manufacturing and heavy engineering with 3D Laser Scanning Metrology are improving. This groundbreaking technology is transforming industries, offering unmatched precision, speed, and efficiency. From superior quality assurance to rapid product development, cost savings, and enhanced customization, the benefits are game-changing. In the realm of heavy engineering, 3D Laser Scanning Metrology is defying the challenges posed by large-scale projects, proving to be an invaluable tool in our technological arsenal. Welcome to the future of industrial innovation, where precision, efficiency, and endless potential are not just ideals, but everyday realities

Revolutionize your Metrology with 3D Scanning - Unlocking Accurate and Detailed 3D Digital Models

Explore the transformative role of 3D scanning and laser technology in metrology, providing precise dimensions and surface details for digital 3D models. This technology revolutionizes reverse engineering and manufacturing, improving design, inspection, and quality control processes across industries. Uncover how 3D laser scanning enhances replication and modification of existing parts, marking a significant upgrade from traditional measurement techniques.

Unlock the Power of 3D Scanning for Reverse Engineering in Metrology.

3D scanning, particularly laser scanning, has revolutionized the reverse engineering process. 3D laser scanners use advanced technology to detect thousands of surface points in just a few seconds, enabling faster and more precise data extrapolation. This technology streamlines the reverse engineering process by accurately capturing the object's surface shape and dimensions, which are then used to create a digital 3D model.

What is Reverse Engineering ?

The Log Book is a bi-weekly digest of curated content offering insights into the use of 3D scanning for Quality control in manufacturing, reverse engineering, additive technologies, 3D point clouds, creation of meshes and modelling in Fusion 360, Inventor and other software.

Also included are links to learnings we have discovered around entrepreneurship and business leadership.

The Logbook #8

The Log Book is a bi-weekly digest of curated content offering insights into the use of 3D scanning for Quality control in manufacturing, reverse engineering, additive technologies, 3D point clouds, creation of meshes and modelling in Fusion 360, Inventor and other software.

Also included are links to learnings we have discovered around entrepreneurship and business leadership.

How does 3d scanning help KTM motor racing win ?

The Log Book is a bi-weekly digest of curated content offering insights into the use of 3D scanning for Quality control in manufacturing, reverse engineering, additive technologies, 3D point clouds, creation of meshes and modelling in Fusion 360, Inventor and other software.

Also included are links to learnings we have discovered around entrepreneurship and business leadership.

Curious thoughts and links

Additive engineering process introduction for engineers, Annual report of state of 3D printing, reverse engineering and 3D scans, coral regrowth experiments using 3D printing

17 reasons why 3D laser scanning, Reverse Engineering, 3d parametric modelling and 3D printing should be part of your workflow.

17 reasons why 3D laser scanning, Reverse Engineering, 3d parametric modelling, Additive engineering and 3D printing should be part of your workflow.