Revolutionize your Metrology with 3D Scanning - Unlocking Accurate and Detailed 3D Digital Models

3D scanning for metrology is a technology that involves capturing the precise dimensions, shape, and surface details of an object by generating a digital 3D model. This technique has significantly enhanced reverse engineering and manufacturing processes in various industries.

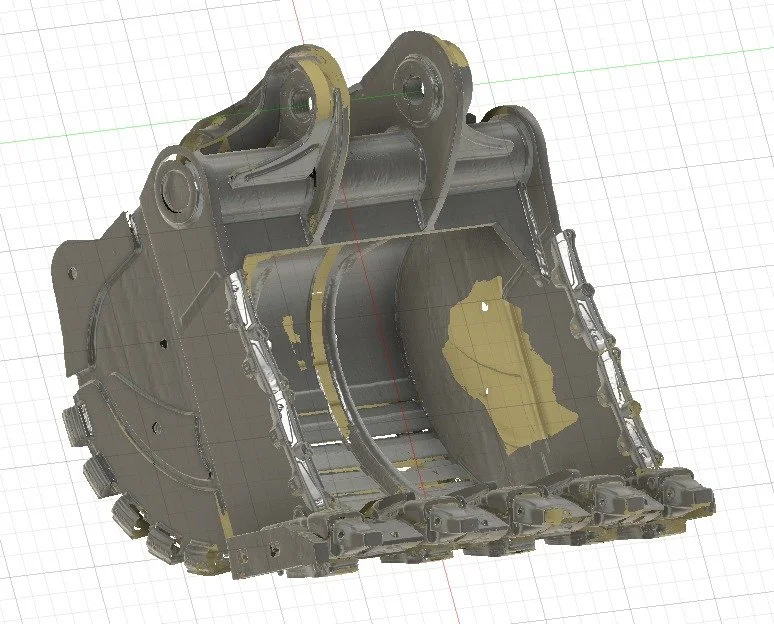

3D laser scanning is a process that utilizes lasers to capture the exact geometry and surface details of an object, resulting in a comprehensive 3D digital representation. This technology operates by projecting millions of laser pulses across and onto the target object and thereby determining the object's precise geometry. It is beneficial in reverse engineering, where it provides an accurate basis for replicating or modifying existing parts. In manufacturing, 3D laser scanning improves the design, inspection, and quality control processes, offering a significant upgrade to traditional measurement techniques.

Here are some ways in which 3D scanning contributes to these areas:

Accurate and detailed data acquisition: 3D scanning provides high-resolution and accurate measurements of complex geometries and surfaces, capturing even the smallest details. This accuracy is essential for reverse engineering, as it helps engineers to recreate the design and functionality of a component or system.

Faster data collection: 3D scanning is a non-contact and non-destructive method, enabling quick and efficient data collection compared to traditional measurement techniques. This faster process reduces the time taken for reverse engineering and accelerates the product development cycle in manufacturing.

Digital archiving and design modification: 3D scanning generates digital models, which can be stored and shared easily. This allows for efficient collaboration between teams and easy modification of designs, facilitating the reverse engineering and manufacturing processes.

Quality control and inspection: 3D scanning can be used to compare the scanned data with the original design specifications, helping to identify deviations and defects. This enables manufacturers to maintain high-quality standards and reduce production errors.

Customization and personalization: 3D scanning enables the capture of unique and complex shapes, facilitating the creation of customized products. This ability to produce tailored items is particularly valuable in industries like healthcare, automotive, and aerospace.

Reducing material waste and costs: By creating accurate 3D models, 3D scanning minimizes errors in the manufacturing process, reducing material waste and lowering production costs.

Integration with other technologies: 3D scanning can be integrated with other digital technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), streamlining the reverse engineering and manufacturing processes.

In summary, utilising lasers to capture the exact geometry and surface details of an object with a level of detail and accuracy that traditional methods often cannot match offers several significant benefits. This technology, overall, enhances efficiency, accuracy, and flexibility in various fields such as manufacturing, industrial production and heavy engineering.