Unlock the Power of 3D Scanning for Reverse Engineering in Metrology.

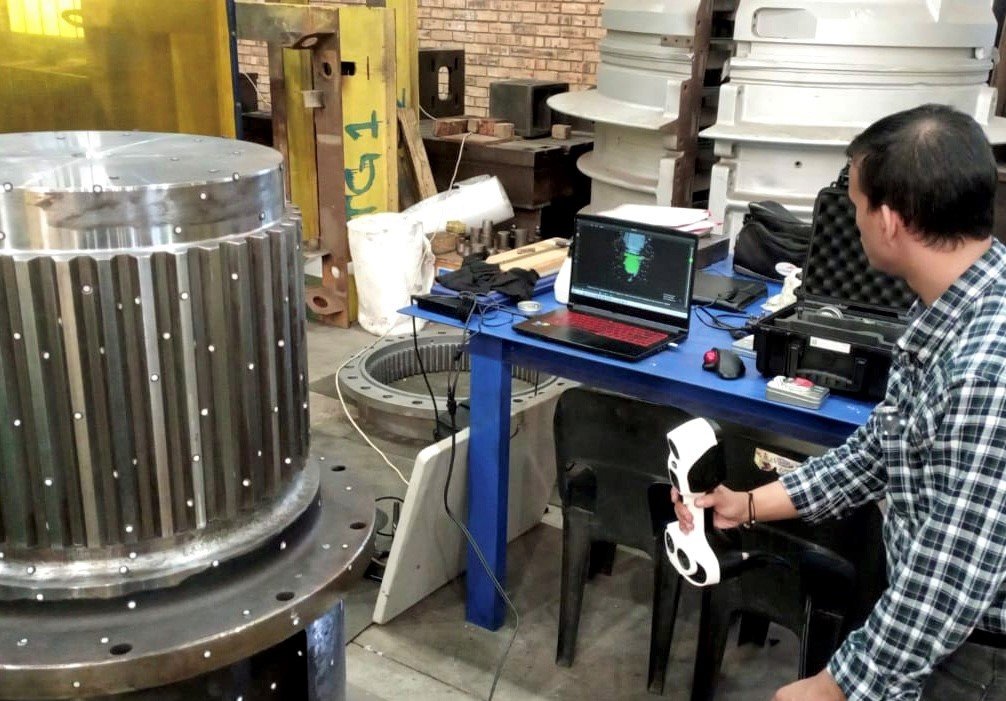

3D scanning, particularly laser scanning, has revolutionized the reverse engineering process. 3D laser scanners use advanced technology to detect thousands of surface points in just a few seconds, enabling faster and more precise data extrapolation. This technology streamlines the reverse engineering process by accurately capturing the object's surface shape and dimensions, which are then used to create a digital 3D model.

What is Reverse Engineering ?

The Log Book is a bi-weekly digest of curated content offering insights into the use of 3D scanning for Quality control in manufacturing, reverse engineering, additive technologies, 3D point clouds, creation of meshes and modelling in Fusion 360, Inventor and other software.

Also included are links to learnings we have discovered around entrepreneurship and business leadership.

The Logbook #8

The Log Book is a bi-weekly digest of curated content offering insights into the use of 3D scanning for Quality control in manufacturing, reverse engineering, additive technologies, 3D point clouds, creation of meshes and modelling in Fusion 360, Inventor and other software.

Also included are links to learnings we have discovered around entrepreneurship and business leadership.